Key Points:

- Geo Oceans won and delivered several successful campaigns in 2023 with tasks including cleaning and inspection of flowlines and mooring chains.

- They used their Reach Bravo 5 and 7-Function lightweight electric manipulators to reduce the time taken to complete cleaning and inspection work by up to 50% according to the operators.

- Operators pointed to the versatility, reach, and ease of use of the manipulators when wielding dredging hoses, high-pressure cleaning lances and other tools, as the main reasons for the efficiency boost.

The Campaigns

Subsea oil fields are comprised of distributed assets such as Wellheads, Manifolds, ‘Christmas Trees’, Platforms, and FPSOs, connected by an ordered spaghetti of flowlines and umbilicals; a quick google image search will show you the metropolis of infrastructure on and under the surface of the ocean in places all around the world. Time is money and so this investment of steel will often live in the harsh ocean environment for as long as it possibly can, sometimes for decades, and battle it out with some of the favourite problems posed by the sea, including corrosion and deformation.

To ensure things don’t go awry – think Deepwater Horizon – it is paramount that regular inspections and health checks of each underwater asset are conducted. So much so that these are mandated, in terms of inspection type and period, by regulators in the offshore energy sector such as BSEE and NOPSEMA.

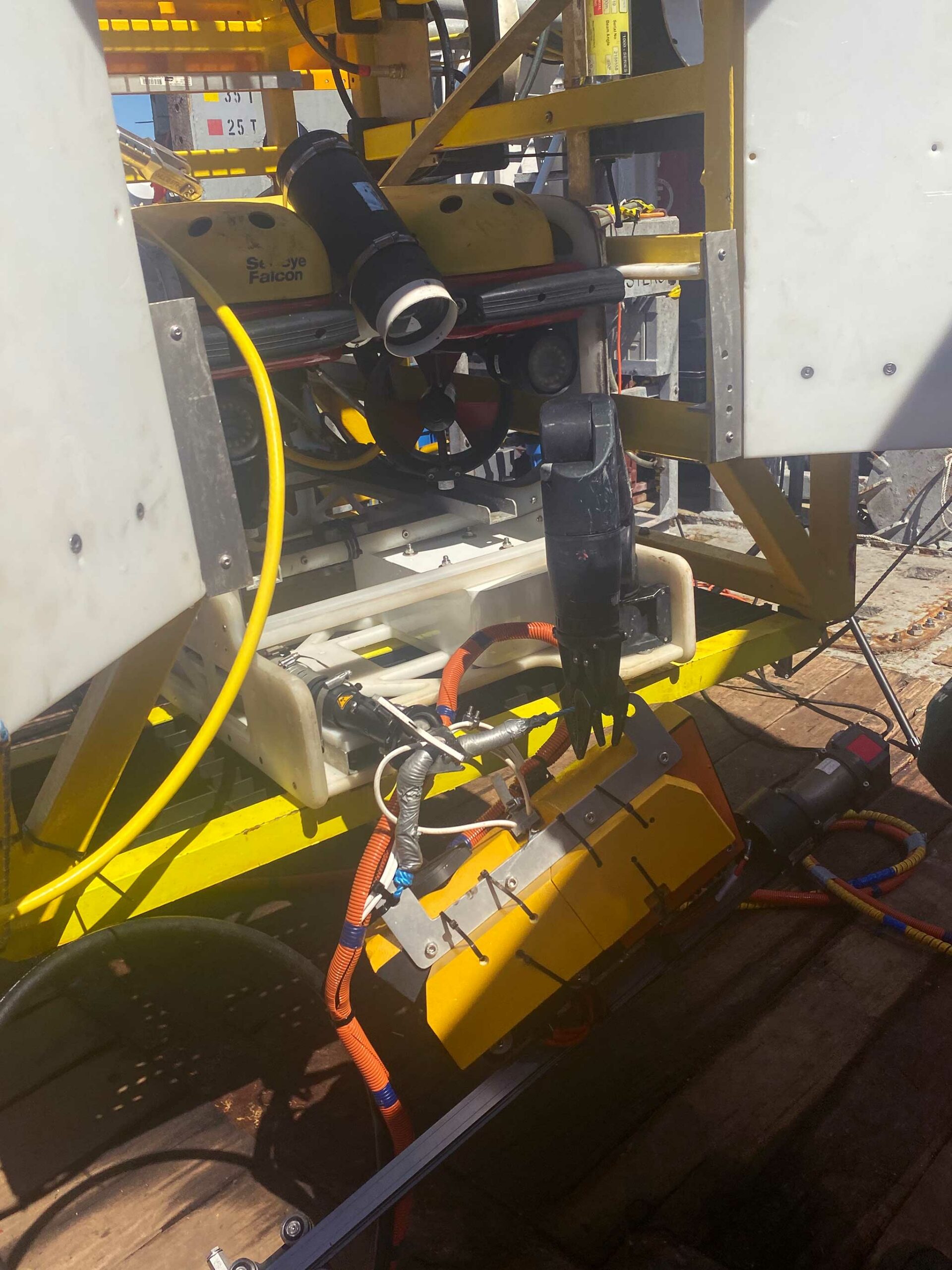

Geo Oceans are a growing, agile, offshore energy Service Provider based in Western Australia. Amongst other things, they’re known for their adept deployments of unmanned systems for subsea inspection including for UWILD (Underwater Inspection In-Lieu of Drydocking), tank inspection, and inspection of oil fields. Geo Oceans has found success in deploying small ROVs that have huge advantages over larger Work Class ROVs in terms of their logistics and operational footprint, thus significantly reducing cost. If you only need to deliver a letter, it’s best not to send an 18-wheeler to do so.

In 2023, this competitive edge led to them being successful in various bids, including for campaigns to conduct inspections of flowlines and FPSO mooring chains. In each of these campaigns there were a series of complex tasks that needed to be carried out, including:

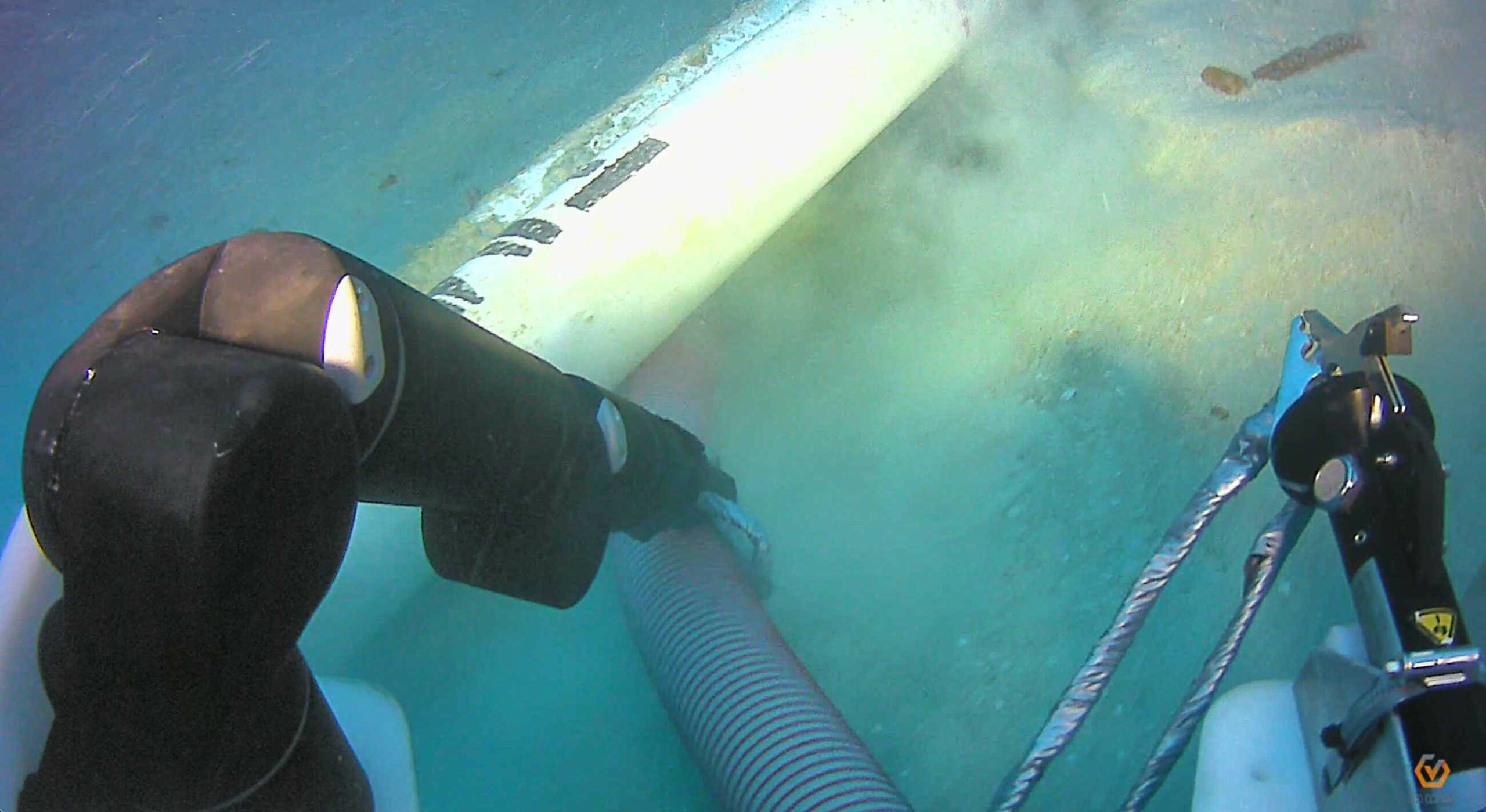

- Dredging around and underneath flowlines and chains to expose inspection areas,

- Cleaning marine growth away from inspection areas using high-pressure cleaning lances, and

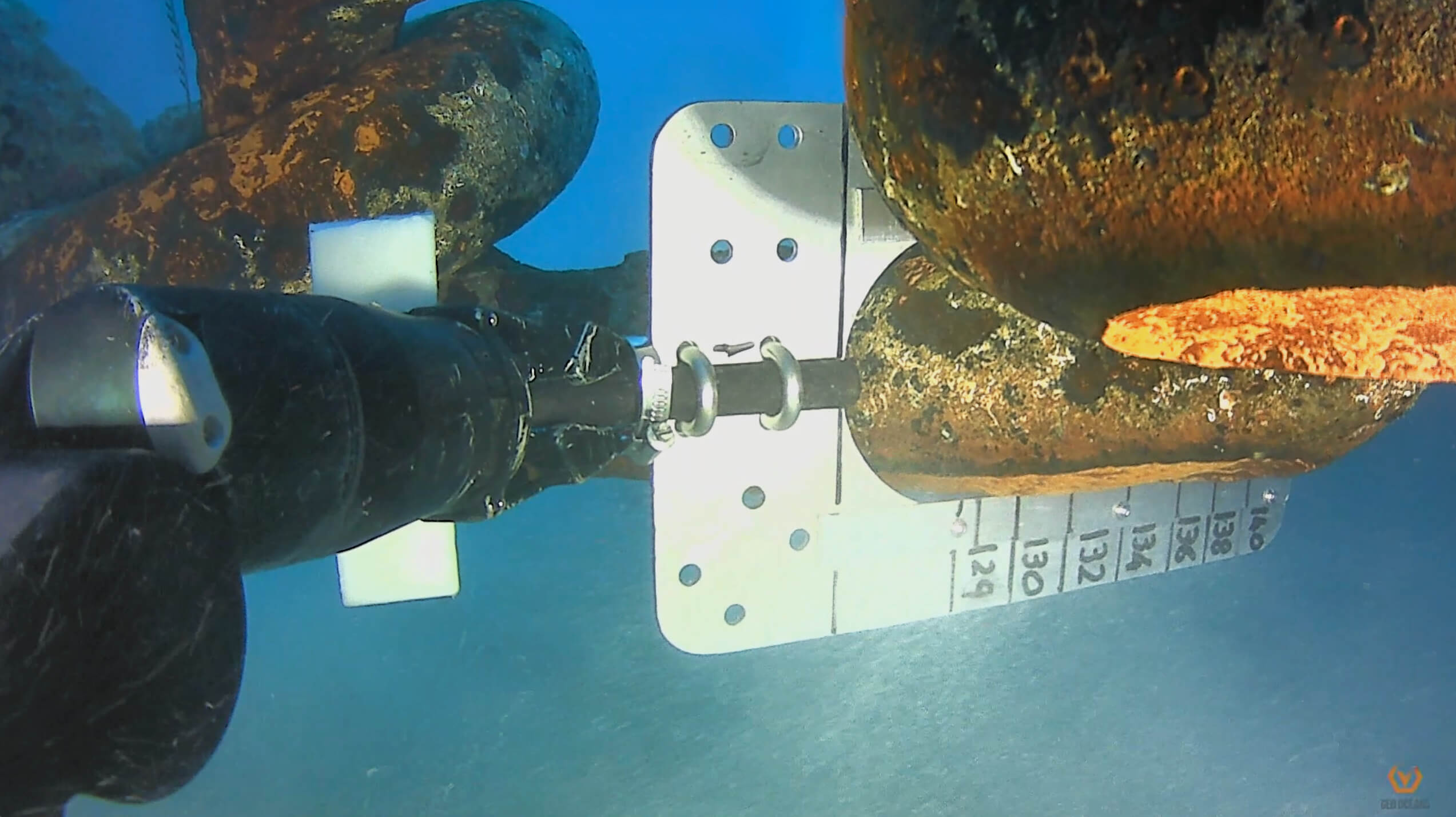

- Moving measurement tooling into precise positions to achieve the required read-out

The Opportunity

How do you make sure you can win work at a competitive rate while ensuring you deliver a high-quality service to your customers? One approach is to continually adopt the latest available technology into your operations to give you an edge.

Here’s an example: For the tasks above, a different tool is required for each, and that tool further needs to be configured to point in the right direction for it to be effective. Historically, this has meant recovering ROVs to the surface every time a tool or orientation change is required. What if there’s a better way out there?

With 30+ inspection points over the campaigns, the opportunity for Geo Oceans was to make the work at each inspection point as efficient as possible using better manipulator technology. Having a way to change the position and angle of tooling accurately, and the ability to switch between tools subsea, would have a massive impact on the time taken to complete dredging, cleaning, and measurement tasks. It would also lead to a reduction in the number of on-deck tool reconfigurations. All said, it could reduce the overall campaign duration on the order of days. Readers in the industry understand the significance of that as a dollar figure.

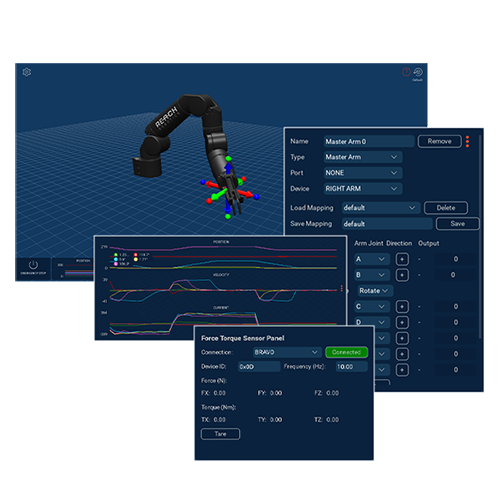

The Product: Reach Bravo 5 and 7-Function Manipulators and Master Arm controller, powered by Reach Control

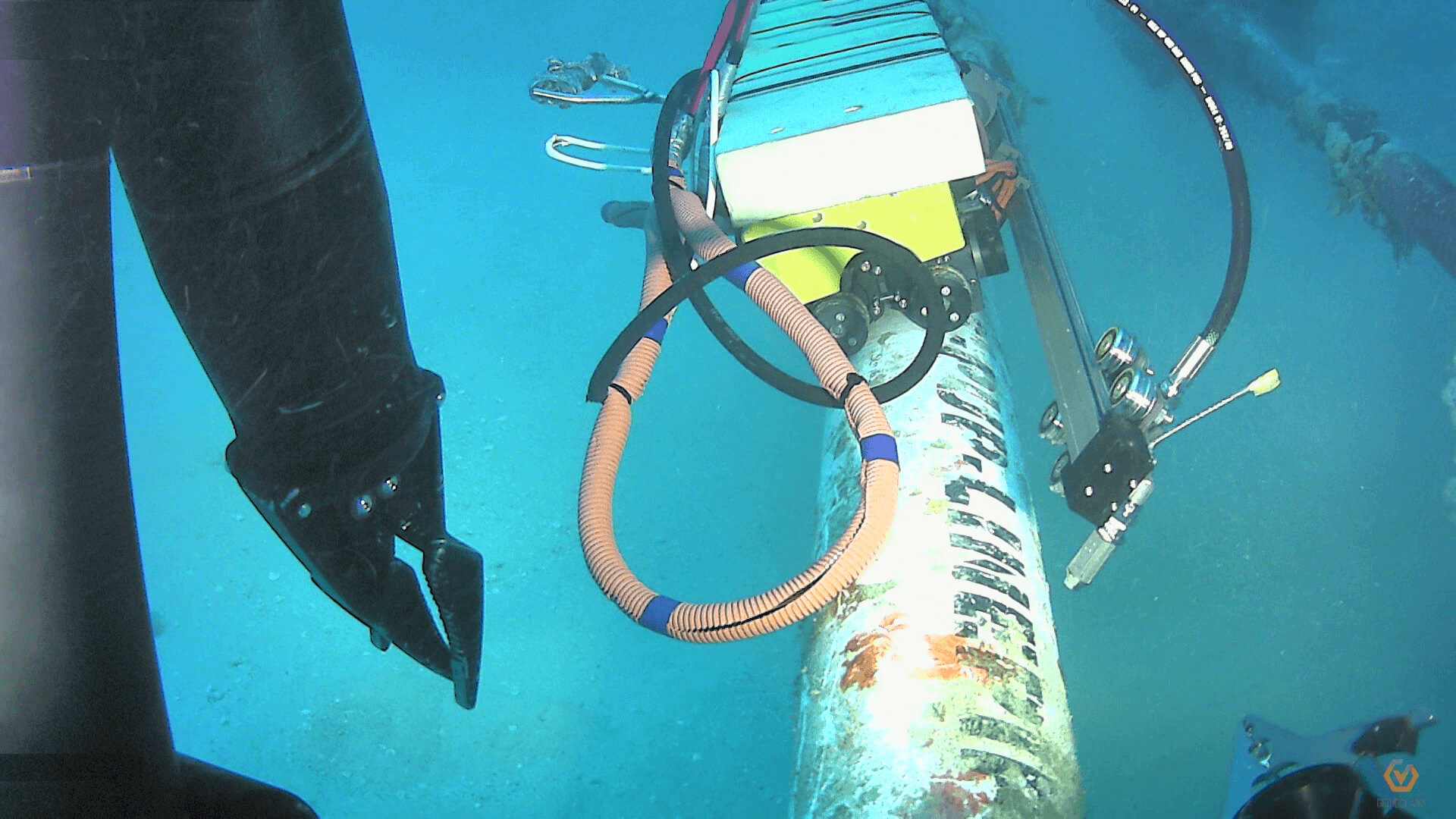

Geo Oceans equipped their Saab Seaeye Falcon ROVs with Reach Robotics Bravo 5 and Bravo 7 electric underwater manipulators.

A technical summary of each manipulator is at the end of this article. In brief, each is a dexterous manipulator designed for inspection class ROVs, just like the Falcon. They can be controlled in several ways, but the Master Arm controller offers the most intuitive way to get the end-effector where you want it. Combined, this system is the inspection class equivalent of flagship Work Class manipulators. With the Bravo, inspection class ROVs can do much more than ever before.

Here’s what was useful for Geo Oceans according to their operators:

- The Bravo’s lift capacity (20kg) made it suitable for manipulating a dredging hose and pressure cleaner, and provided the inherent strength necessary for handling the minor knocks that can occur during cleaning tasks.

- The arm’s reach and dexterity enabled finer placement of the dredging hose and cleaning lance. Geo Oceans had previously used less dexterous technology which meant the ROV needed to be moved more frequently to get a tool to the required position. This is a notoriously ‘jerky’ operation, with overshoot and over-correction being a common phenomenon. It also stirs up excess sediment, obscuring the field of view. With the Reach Bravo they noted its ability to reach into a wider range of positions, including under flowlines, while the ROV remained stationary sitting on the seafloor.

- Where other manipulators require heavy, large skid components, the Reach Bravo doesn’t, and so left the ROV in a better state for piloting smoothly and with more capacity for other payloads to be mounted simultaneously.

- From a control perspective, the Master Arm controller gave the operator a quicker and more precise method to adjust the nozzle of the cleaning tool to get into confined spaces. When carrying out measurement tasks, such as with a Go-No-Go Guage, the ability to make fine adjustments to the tool’s orientation made each inspection far quicker and required less ROV re-positioning.

The Result: Fast and accurate cleaning and measurements resulting in days saved over the course of the inspection campaigns

It can be hard to quantify the efficiency gained and time saved by implementing a new process or technology. And in a case study authored by the manufacturer, would you believe it anyway? We try not to infuse our bias and instead ask the operators. Based on his experience across a long history of subsea operations, ROV Pilot Glen Porter estimated a reduction in operational time by 50-75% for each cleaning and measurement task. Considering each inspection point could take up to 4-5 hours this has a significant impact on the overall campaign length.

“Looking at the cleaning and gauging tasks, the manipulator easily reduced the operational task time by between 50% and 75% depending on the task because of the better usability, dexterity, and range of motion of the system”.

~ Glen Porter, ROV Pilot from GEO Oceans

When asked about the overall benefit offered by the Bravo to their operations, he said,

“The Bravo enables us to extend the capabilities of our inspection-class ROV, conducting tasks of a complexity arguably reserved for Work Class vehicles. We could not have performed the same tasks nearly as easily, or at all, with other manipulators of similar size.”

“It also increased efficiency by reducing tooling reconfiguration times on-deck and reducing the subsea operational time by up to 50% depending on the task, through better usability and control authority. For example, we don’t have to do joint-by-joint control, and can instead ‘cut the corner’ to move the tool more quickly to where it needs to be”.

~ Glen Porter, ROV Pilot from GEO Oceans

Have questions about this case study? Contact us today.

ProductS IN DETAIL

The Bravo 7 and Bravo 5 are tough, lightweight, electric manipulator arms changing the remote operations landscape through advanced usability and pointing accuracy in a compact package. Designed for inspection class ROVs such as the Saab Seaeye Falcon and Seatronics VALOR, the manipulators are straightforward to integrate and paired with an intuitive topside software interface, Reach Control. The Bravo 7 is a 7-Function arm, with just shy of 1m reach, capable of lifting 10+kg at full extension. The Bravo 5 is a 5-Function arm, 0.75m reach, and can lift 15kg at full extension.

The Master Arm is an intuitive one-to-one control method. Wherever the operator moves the master arm, the manipulator follows. Designed to make manual tasks smoother, more accurate, and quicker than traditional ‘bang bang’, joint-by-joint controls, this control option is a must for regular offshore operators.

The Reach Control is an advanced Human Machine Interface (HMI) providing intuitive control between operator and manipulator system. Reach Control features include kinematic control and workspace definition to enable the execution of complex tasks in remote and hostile environments.

Want to explore what the new generation of subsea intervention technology can do for you? Get in touch today.