Reach Robotics develops robotic manipulators (also known as robotics arms) for harsh environments. This general guide explains a manipulator, its different con

Reach Alpha ROV Manipulator Arm For Harsh Environmentfigurations, and its widespread use in real-world scenarios.

What is a robotic manipulator?

A robotic manipulator is an electronically controlled equipment that contains a set of electric, electronic and mechanical components.

These jointed segments loosely resemble a human arm with a varying range of motion and dexterity.

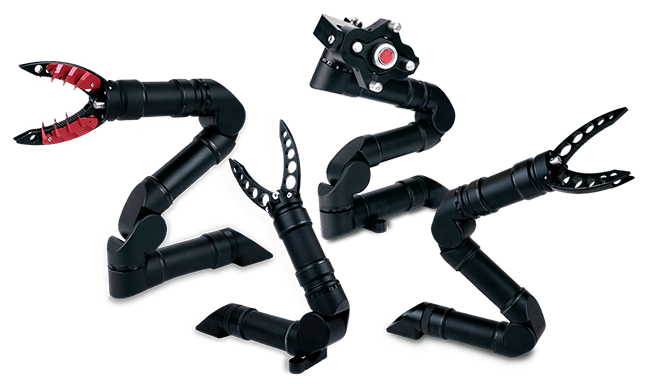

The end-effector is interchangeable, offering diverse solutions to meet specific task requirements and vary in form and function from claws to cutters.

Which ROV Manipulator arm is best?

Robotic manipulators vary in size, function, and degrees of freedom, making different configurations appropriate for different missions. For example, the Reach Alpha range (for smaller platforms) is suitable for Portable Class ROVs, while the Reach Bravo (for larger platforms) is suitable for Inspection Class ROVs.

The capacity of the manipulator’s arm depends on the number of degrees of freedom. Degree of Freedom (DoF) is an independent joint that can provide freedom of movement for the manipulator, either in a rotational or translational (linear) sense. Every geometric axis a joint can rotate around or extend is counted as a ‘single degree of freedom.’

With Reach Robotics manipulators, the number after the model name refers to the functions of the arm. For example, the Reach Alpha 5 has five functions; four degrees of freedom in the joints plus the linear end-effector function.

Reach Robotics manipulators come with interchangeable jaws (also known as a gripper) at the robotic arm’s end. To open or close the jaws, we use a prismatic actuator (a fancy word for an actuator that only operates along a single axis). We define the reference point as a floating location between the manipulator’s jaws. As the manipulator moves, this location is updated regarding the end-effector’s position. If you want to grab something at position (x,y,z) with orientation (a,b,c), this position is optimized in the inverse kinematics algorithm. Because of this, the movement of the linear actuator to open and close the manipulator’s gripper does not change the reference point; thus, it does not provide a degree of freedom. ‘

Hydraulic vs. Electric Manipulator Arms

Reach Robotics manipulator arms are all-electric. As compared to hydraulic arms, electric manipulators are smaller, lighter, and have higher accuracy allowing for more advanced functionality and precise control of the end-effector.

Uses for ROV Manipulator Arms

A variety of subsea and on-land tasks can use the ROV manipulator. For example, in robotics, the ROV manipulator arms are devices that shift heavy and dangerous materials underwater without the operator’s contact increasing flexibility in work. For more detail, see: Top Uses for Underwater Manipulators. Manipulator’s arms are often used on crewless ground vehicles, underwater ROVs, and other major applications that operate in harsh environments.

Why choose Reach Robotics Manipulator Arms?

We offer lightweight design manipulator arms, good performance, and increased lift capacity at Reach Robotics. Our manipulator’s arms help in underwater tasks like construction, repair, and shifting heavy machine tools. The underwater ROV manipulators can be used in various fields. We are trying to decrease and solve industrial problems regarding underwater manipulation and control.