When describing Reach Robotics manipulators, it’s common for us to cite depth, strength and robustness as significant features which make our arms advanced. Far from being ‘robotics buzzwords,’ these concepts are meticulously researched, designed, tested, and verified by our team of engineers. Our expert Embedded Control Systems Engineer, Kyle Mclean, helps break this down, explaining what makes the Bravo Mk2 our most advanced manipulator series yet.

DEPTH

As our operators in Oil and Gas, Renewable Energy, Defence and Search & Recovery seek to replace human divers with robotic arms, there is demand for higher depth rating to increase capability. The more instances in which we replace divers with robots, the less human risk is associated with subsea tasks.

How did Reach Robotics’s R&D team increase Reach Bravo’s depth rating?

The Bravo Mk2 is currently depth rated to 450m, with developments underway to increase this to 600m. This is made possible by altering the design of the mechanical structure to minimise stress due to water pressure. The process includes:

- Finite Element Analysis to determine where stress concentrations are along the arm.

- Optimizing the design to minimize stress from external pressure.

- Customisation of O-ring surfaces and material to form a more resistant seal.

STRENGTH

The stronger the manipulator, the more capable it becomes in real-world operations. Strength not only refers to the lift capacity of the Bravo arm (10kg+), but also its wrist torque (20Nm) and force of the jaws (10000N+).

How did our engineers increase strength for the Bravo Mk2 series?

- We redesigned the motor architecture to increase joint rigidity and drastically increase reliability

- We developed a high force end-effector (up to 10Kn) by redesigning the liner actuator, enabling a higher push/closing force.

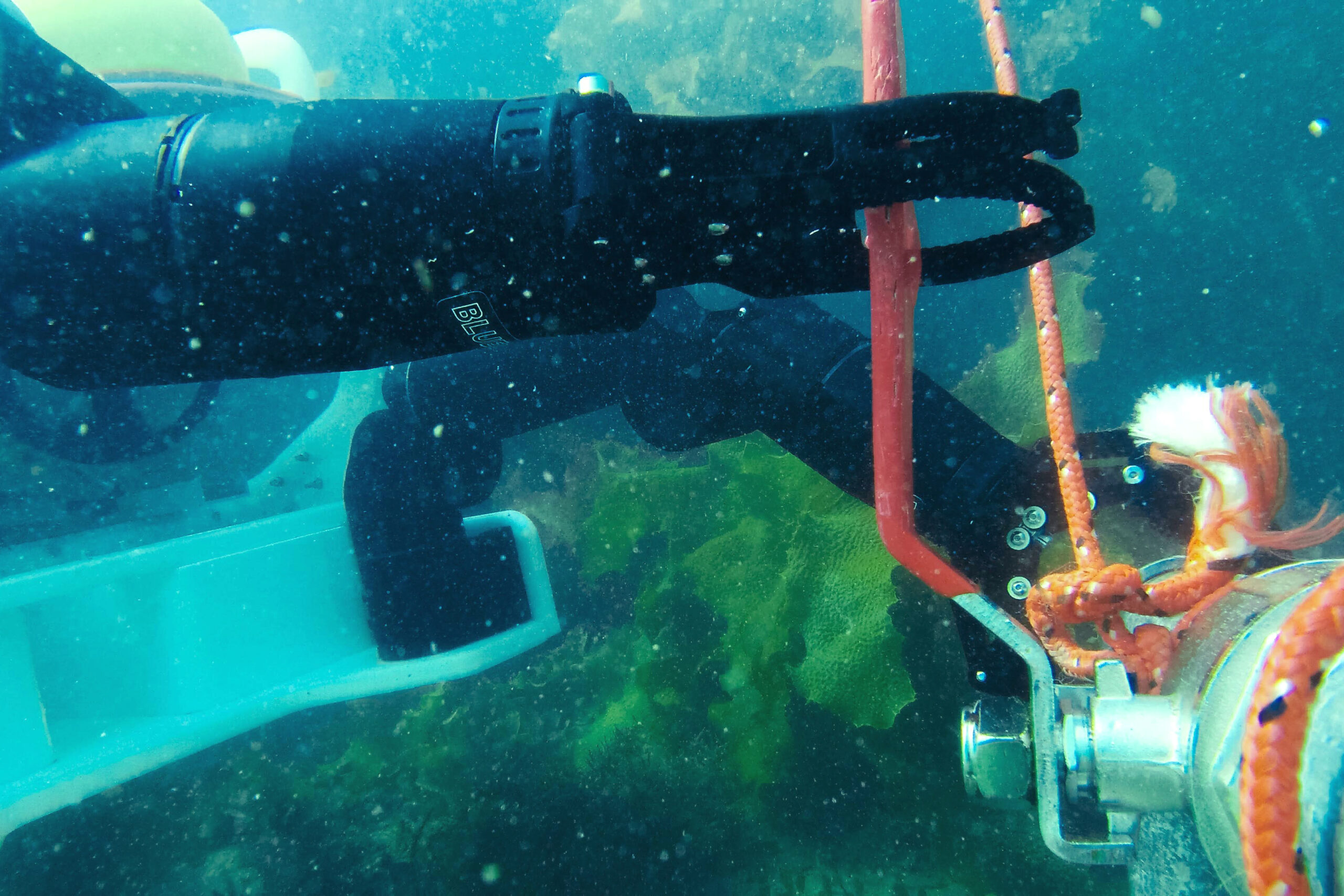

- Developing inter-changeable jaws to allow for fast and dextrous applications or high-force cutting capability with enough force to sever through 1ӯ rope or cable.

ROBUST

Operators continue to deploy our manipulators in increasingly unpredictable environments. Faced with variable external obstacles, robotic arms must remain highly capable for mission success. The Reach Robotics R&D team have taken this into account throughout their design and testing process for Bravo Mk2.

What features and upgrades ensure our manipulator is robust?

- We’ve added slip rings to all rotated joints making continuous 360° rotation possible.

- We upgraded our Software system:

- Optimized the Bravo’s collision avoidance capability to account for higher joint speed by reducing the time required to predict and respond to potential collisions

- Included available torque/velocity monitoring to determine the current performance window of the system, ensuring it’s more robust to disturbances.

- Optimized the Bravo’s collision avoidance capability to account for higher joint speed by reducing the time required to predict and respond to potential collisions

- We upgraded our Electrical System:

- Increased Electrostatic Discharge protection to all sub-systems to aid in the protection of the electrical system

- Included reverse polarity protection to overcome user error if powered incorrectly.

- Incorporated Over-current protection to protect the Bravo from power supply faults.

- Increased Electrostatic Discharge protection to all sub-systems to aid in the protection of the electrical system

The changes we implement result from hours of dedicated R&D in response to critical customer feedback. They challenge us to produce stronger, more robust robotic arms that withstand increasingly harsh environments.

If you’re interested in learning more about the Bravo MK2, enquire here or email sales@reachrobotics.com